Across Africa and other resource-rich regions, the conversation around mining is shifting. It’s no longer just about extraction. The real value lies in what happens after the minerals are extracted from the ground. This is where mineral processing and value addition become critical.

If developing countries are to truly benefit from their mineral wealth, beneficiation must be treated as a strategic priority. That includes integrating technologies that improve efficiency, safety, and final product quality.

In recent years, several African countries have taken bold steps to maximize value from their natural resources by restricting or banning the export of unprocessed minerals. For instance, Zimbabwe has banned the export of raw lithium, urging local processing to support domestic battery manufacturing industries. Similarly, Namibia and Tanzania have implemented policies aimed at promoting local beneficiation of critical minerals like copper, graphite, and rare earths. These shifts signal a broader continental movement toward value addition and economic sovereignty. For mining enterprises operating in this evolving landscape, upgrading mineral processing capabilities is no longer optional, it’s a strategic necessity.

Understanding Value Addition in Mineral Processing

Value addition refers to the processes that enhance the economic value of raw minerals before they reach the market. This includes activities like crushing, grinding, concentration, chemical treatment, and surface modification.

While much attention is often given to upstream extraction methods, downstream beneficiation has the potential to create more local jobs, attract higher export earnings, and reduce dependence on imported finished products.

The Role of Lime in Mineral Processing

In many mineral beneficiation circuits, calcium hydroxide, commonly referred to as slaked lime, plays a vital role. It is widely used for pH control during flotation and neutralization processes. When produced properly, it helps optimize chemical reactions, improve mineral recovery rates, and enhance overall process safety.

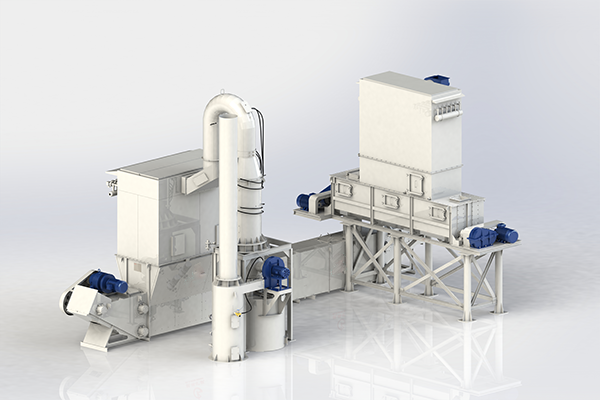

Establishing a dependable calcium hydroxide production line can bring consistency and quality assurance to small and medium-scale mineral processors. Whether it’s for gold processing, base metals, or industrial minerals, lime remains a cornerstone of clean and efficient beneficiation.

Why Surface Modification Matters

As the market demands more refined and specialized mineral products, surface treatment is gaining importance. This process involves modifying the outer properties of fine mineral powders to improve their performance in downstream applications such as paints, plastics, ceramics, or coatings.

One commonly used technique is powder surface modification, where chemical agents are applied to change the hydrophobicity or dispersibility of mineral particles. This allows them to mix better with other materials and reduces waste in final product manufacturing.

For processors aiming to improve compatibility and product quality, investing in a Powder Surface Modification Machine can be a smart step toward innovation and market competitiveness.

A Call to Modernize

Africa’s mining sector has the potential to do more than export raw commodities. By upgrading mineral processing facilities and embracing modern machinery, we can retain more value locally and support industrial growth across the region.

From lime slaking to surface engineering, the right tools and technologies make all the difference. It is time to move from extractive thinking to transformative action. With smart investments and technical support, mineral-rich countries can build industries that deliver long-term benefits to communities, businesses, and economies.